The need of drying fruits and vegetables

Fruits and vegs are rich in vitamins, minerals, phenolics and bioactive phytochemicals. However, they generally have a short shelf-life due to their high water content. Therefore, different food processing techniques such as canning, drying or transforming into stable forms (leathers, pestil or jam) is used to increase shelf life of fruits and vegetables.

Among different processing techniques, drying is gaining much more interest because of the changing lifestyle. Recently, consumers are demanding foods that have relatively short preparing time such as soup mixes, cake mixes and ready to serve meals. Formulation of these type of foods generally requires dried fruit and vegetables powders or flakes. Therefore, fruit and vegetable processing industry is a pioneer in the use of drying technologies.

Common drying techniques in fruit and vegetables industry

More than a dozen of different drying techniques can be used in drying of fruits and vegetables. Some of these techniques can be used in production of whole or sliced dried fruit and vegetables, while other techniques is suitable for powder or flake forms. Common techniques for production of fruit and vegetables powders are outlined below.

Spray drying

In this technique fluid and semi fluid wet materials are atomized into hot air stream (generally higher than 150ºC) to obtained dried particles. Spray drying is one of the rapid, scalable and economical drying technique. Due to vast availability of spray dryer in the market, it is one of the highly used technique in fruit and vegetable industry.

On the other hand, spray drying of sugar rich materials as fruits and vegetables is challenging. Due to the glass transition temperature being exceeded due to the high temperature applied during drying, the material is lost by sticking to the dryer walls. Therefore, sugar rich products requires to add some drying aids (maltodextrin, proteins etc.) to increase drying yield. This situation is undesirable in many products due to the composition change. Additionally, high temperature and surface area cause degradation of heat sensitive components. Moreover, physical properties of spray dried materials (which is important in instant products) are worser than other drying techniques.

Drum drying

Freeze drying

Refractance window drying of fruits and vegetables

Fruits and vegetables are the mostly studied materials in refractance window drying in scientific studies. In the first studies, fruit and vegetable juices and purees were dried to obtain dried powder or flakes, while in the later studies, drying of fruit pulp, fruit leather and slices were studied.

Nindo and Tang (2007) reported that the refractance window drying is effective in drying of high sugar products that are difficult to dry using other techniques, such as spray drying.

Kaspar et al (2012) compared the effects of freeze drying, drum drying, and refractance window drying on the degradation of bioactive components of white, yellow, red and purple potatoes. According to the results of this study, the total phenolic content of the products did not differ according to the drying method and potato color. However, the highest total anthocyanin content losses in red and purple potatoes were determined in the drum dryer. Similarly, the total amount of carotenoids in yellow potatoes was found to be lower in the drum dryer. As a result, it has been suggested to apply refractance window drying, taking into account the drying costs.

Nindo et al (2003) determined the thermal efficiency of refractance window drying and the effect of reducing microbial load in pumpkin drying. The thermal efficiency was found to be between 52-70%. It has been reported that there was a 4.6, 6.1, 6.0 and 5.5 log reduction in the total aerobic bacteria, coliform, Escherichia coli and Listeria innocua counts during the 5 min drying period, respectively.

Caparino et al. (2012) produced mango powder with 4 different methods (freeze drying, drum drying, spray drying and KPK) and investigated the physical properties and microstructure of the obtained powders. The drying time was 3 minutes in refractance window drying, 31 hours in freeze drying, 54 s in drum drying, and 1-3 s in spray drying. The sample closest to the puree in terms of color was determined as the sample produced with refractance window drying and followed by freeze drying. The highest porosity was determined in the samples produced by freeze drying and spray drying methods. Powders produced by refractance window drying and freeze drying methods had similar hygroscopicity. As a result, it has been determined that the product can be produced with refractance window drying, which is much better than the powders produced by drum drying and spray drying, and has similar properties to the powders produced by freeze drying.

In a study by Abonyi et al. (2002) in the effects of spray drying, freeze drying, drum drying and refractance window drying on the physicochemical properties of strawberry and carrot powders were determined. The losses of otal carotene, α-carotene and β-carotene content were similar in refractance window drying and freeze drying methods and lower than other drying methods. Similarly, the loss of ascorbic acid was determined as 6% in both methods.

Nindo et al (2003b) investigated the effects of freeze drying, tray drying, fluid bed drying, microwave assisted fluid bed drying and refractance window drying methods on asparagus drying kinetics, product color and phenolic content. Refractance window drying took much shorter time to complete drying. Color change was determined at the lowest in freeze drying, followed by fluid bed drying and refractance window drying, respectively. Total antioxidant activity was found to be similar in freeze drying and refractance window drying and higher than other methods. The highest amount of ascorbic acid was determined in the samples dried with refractance window drying.

In a study in which the effects of spray drying, freeze drying and refractance window drying methods on the physicochemical properties of pomegranate powder were determined, the least color change was obtained with the freeze drying method. However, refractance window drying provided the best protection in terms of total anthocyanin content. Moreover antioxidant activity of the products produced by freeze drying and refractance window drying methods were similar. Additionally, it was calculated that freeze drying consumed 30 times more energy than refractance window drying (Baeghbali et al. 2016).

Jafari et al. (2016) investigated the effect of convective drying and refractance window drying of kiwi slices on the drying characteristics and physicochemical properties. The increase in thickness and decrease in drying temperature in both drying increased the drying time. At 80 and 90ºC temperatures, refractance window drying time was shorter by approximately 100 and 50 minutes compared to convective drying, respectively. However, both drying methods were completed in a similar time at 100ºC. It was determined that the products dried by the refractance window drying had better textural and organoleptic properties.

Hernández-Santos et al (2016) determined the effect of convective drying and refractance window drying of carrot slices of different thicknesses (2 and 4 mm) at different temperatures (74 and 94ºC) on the drying characteristics and physicochemical properties of the product. The refractance window drying method shortened the drying time by 26-51% compared to the convective drying method. It was determined that there was no statistical difference between refractance window dried product and fresh carrot in terms of color, total phenolic content and antioxidant activity. However, no difference was found between the drying methods in terms of texture.

Tomato paste drying with InfraRWD

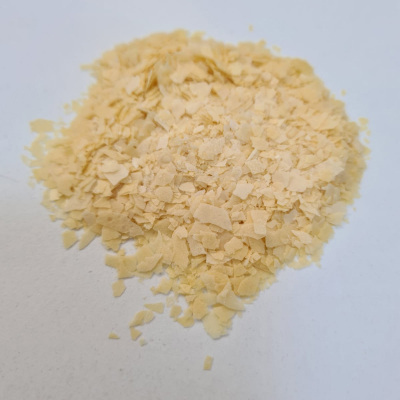

Banana flakes produced by refractance window drying

Comparison of refractance window drying with other drying techniques

Refractance window drying has some advantages over other drying techniques as stated above. Some of these advantages.

Rapid

Refractance window drying is much faster than convective drying (tray, oven or belt dryers) and freeze drying techniques.

Better bioactivity

The chemical properties are comparative to freeze drying and or better than other heat involved drying techniques

Continuous

Refractance window drying works continuously, and therefore suitable for full scale production

Economical

Both capital investment and operating cost of refractance window drying is economical than other techniques.

Instant

Physical properties such as solubility, porosity and bulk densities of refractance window dried products much better than other drying techniques

Heat induced contaminants

Refractance window drying cause no or low fprmation of heat induced contaminants such as HMF, acrylamide etc.

InfraRWD drying of fruits and vegetables

In addition of the advantages of refractance window drying of fruits and vegetables, InfraRWD offered some developments and new advantages.

up to 40%

Reduction of drying time compared to refractance window drying

up to 35%

Reduction in consumed energy compared to refractance window drying

up to 2x

Increase in the capacity compared to refractance window drying

Flexibility

InfraRWD dryer can be used in three different mode, namely refractance window drying, infrared drying and infrared assisted refractance window drying. Therefore, a wide range of product with different charateristics can be produced using an InfraRWD dryer.