Need for drying in meat, dairy and protein industry

Milk and whey powders are produced to stabilize these products for their storage and later use. Milk and whey powders are used mostly for human consumption, animal feeds and ingredients in food formulations. Additionally, the dairy industry has been forced to look for better uses for by-products due to legal and environmental reasons.

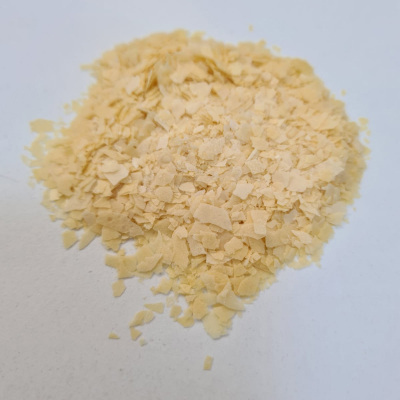

Therefore, the dairy industry has developed new value added products such as milk protein concentrate/isolate, whey protein concentrate/isolate, milk powders, sodium casseinate, whey concentrates, and demineralized whey concentrates.

Common drying techniques in meat, dairy and protein industry

The commonly used technique for the dehydration of dairy products is spray drying.

A dairy powder is characterized not only by its chemical composition but also by its microbiological and physical properties. All of these characteristics depend on drying parameters, the properties of the raw materşal before drying and storage conditions.

The nutritional quality of dairy powders depends on the intensity of the during. Thermal processing induces physicochemical changes such as loss in vitamin content, reduction of available lysine content and denaturation of proteins or to produce nutritional compounds such as lactulose.

Refractance window drying of meat, dairy and proteins

Refractance window drying was employed to produce different meat, dairy and protein powders. Some of these studies were outlined below.

In a recent study, Tontul et al (2021) comparatively researched refractance window drying and freeze drying in kefir powder production. According to study, refractance window drying provided better flowability and cohesiveness in kefir powder. Moreover, better wettability, hygroscopicity and solubility was observed in refractance window dried powders compared to those of freeze drying. As expected slightly higher inactivation of beneficial microorganisms observed in refractance window drying. The survival of beneficial microorganisms in the kefir powders produced by refractance window drying at 50 °C was higher tan those of 60 and 70ºC at the end of storage.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Aykin-Dincer et al (2021) produced bone broth powder using refractance window drying. The study showed that refractance window drying allowed drying with high yield. Increasing drying temperature caused slight increase in TBARS value but TBARS value of freeze dried and refractance window dried sample at 50ºC was similar. Moreover, The bone broth powder produced by refractance window drying had better sensorial and microbial quality. The authors claimed that refractance window drying has high potential to be used in bone broth powder production.

Preethi et al (2021) compared refractance window drying and freeze drying in the production of plant based protein isolate from two different pulses (green gram and black gram). Refractance window dried protein powders showed excellent powder characteristics according to Carr index and solubility. Both drying techniques yielded similar oil absorption capacity, surface hydrophobicity, gel formation, pasting and thermal properties. The study clearly showed that refractance window drying offered protein quality in par with freeze drying.

van’t Land and Raes (2019) used refractance window drying in preservation of fish silage. The authors showed that the properties of final product depended on application thicknesses, degree of protein-hydrolysis, and ambient conditions.

Tontul et al (2018a) investigated the usability of refractance window drying in yoghurt powder production and compared the properties of final product with freeze dried counterparts. Physical properties of yoghurt powders obtained by refractance window drying were generally better than those of freeze drying except for colour properties. On the other hand, refractance window drying caused reduction in the counts of yoghurt bacteria during drying, and this reduction increased as the drying temperature increased. The authors reported refractance window drying at 50 °C as an alternative method for production of yoghurt powder with improved physical properties.

Tontul et al (2018b) investigated the effect of refractance window drying on the technological properties of chickpea protein isolates and compared it with freeze drying. The solubility, oil holding capacity and foam stability of the freeze dried protein isolates were determined to be better compared to that of refractance window drying. On the other hand, the refractance window dried samples had better water holding capacity and emulsion stability. The study showed that the drying technique had significant effect on technological properties or plant based proteins.

Rostami et al (2018) produced meat powder by drying of meat slices using refractance window drying. The study showed that meat powder produced by refractance window drying had good physical properties. The authors claimed that refractance window drying results in better characteristics of the final powder in comparison with other available drying techniques of meat products.

Comparison of refractance window drying with other drying techniques

Refractance window drying has some advantages over other drying techniques as stated above. Some of these advantages are:

Rapid

Refractance window drying is much faster than convective drying (tray, oven or belt dryers) and freeze drying techniques.

Better chemical properties

The chemical properties of powder produced by this technique is comparative to freeze drying and better than other drying techniques

Continuous

Refractance window drying works continuously, and therefore suitable for full scale production

Economical

Both capital investment and operating cost of refractance window drying is economical than other techniques.

Better physical properties

Physical properties such as solubility, porosity and bulk densities of refractance window dried products much better than other drying techniques

Heat induced contaminants

Refractance window drying cause no or low formation of heat induced contaminants such as HMF, acrylamide etc.

InfraRWD drying of egg

In addition of the advantages of refractance window drying of egg, InfraRWD offered some developments and new advantages.

up to 40%

Reduction of drying time compared to refractance window drying

up to 35%

Reduction in consumed energy compared to refractance window drying

up to 2x

Increase in the capacity compared to refractance window drying

Flexibility

InfraRWD dryer can be used in three different mode, namely refractance window drying, infrared drying and infrared assisted refractance window drying. Therefore, a wide range of product with different charateristics can be produced using an InfraRWD dryer.